|

| Search | Car Forums | Gallery | Articles | Helper | AF 350Z | IgorSushko.com | Corporate |

|

| Latest | 0 Rplys |

|

|||||||

|

Show Printable Version | Show Printable Version |  Email this Page | Email this Page |  Subscribe to this Thread

Subscribe to this Thread

|

|

|

Thread Tools |

|

|

#1 | |

|

Big Tall Dumb Ass

Join Date: Dec 2003

Location: Deep Dark Doo-Doo

Posts: 1,304

Thanks: 15

Thanked 27 Times in 26 Posts

|

OMG Coolant System Corrosion w/Pics!

This is an extreme case of corrosion on my 2000 GMC Jimmy SLE 4.3L V6 Intake Manifold.

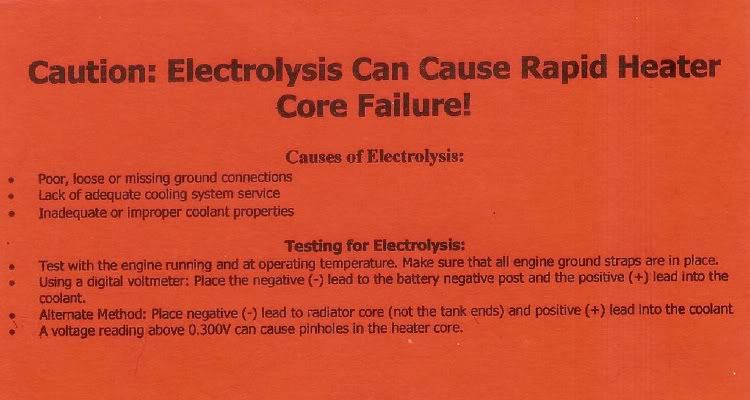

This engine had almost exactly 173,000 miles on it when this happened and the Intake manifold gaskets were replaced at approximately 75,000 miles. This is not about Dexcool or ethylene glycol. This is about proper cooling system maintenance, acidic etching, and possibly electrolysis. This hole actually started out as a pinhole Coolant leak. Simple wire brushing opened up a corroded ½ inch diameter hole through the Aluminum Casting, which would have resulted in a massive coolant leak. The outer area has been cleaned up with a wire brush for clarity. The big hole on the right is for the Distributor. This corroded hole is on the rear, passenger side of the engine. This manifold was replaced with a brand new one, and will not be used again. It is scrap metal.  The cone shaped wire brush actually started out looking like the one with the red handle. These are actually plumbing brushes available at your local hardware store for a couple of bucks. I removed the plastic handle and twisted the remaining wire handles together so I could chuck it up in a drill motor to clean the hole. I used the Goof Off with the wire tooth brush to clean the grease away from around the hole for good bonding. The QuikSteel is a putty that comes in a tube, but wrapped in plastic. It has an inner core that is black, while the outer layer is grey. You cut off what you need (about an inch in this case) and knead with it your fingers until it has a consistent color, then push it into the hole and surrounding area. The putty starts to cure and harden in 5 minutes, but I let mine set up for an hour before filling and testing.  This is the same hole after patching. I patched it while it was still attached to the engine, and miraculously, the patch held. I attached a radiator pressure tester to the system after the patch had cured and only had 2 tiny little pinhole leaks around the edge of the patch at 10 lbs of pressure. Not wanting to blow the patch out of the hole, I decided not to go to 15 lbs. Instead I added a Radiator sealer to take care of the tiny pin holes. I drove the truck in this condition for two weeks waiting for replacement parts to arrive via the internet.  This is the opposite side of the manifold that contacts the head. The little black spot is the plug poking through the corroded hole.  Same view after wire brushing. This port in the manifold is actually blanked off, meaning the Manifold is actually cast shut on this port. However, this surface is exposed to the coolant jacket of the head. The casting in this area is approximately a ¼ inch thick and as you can see, the Aluminum corroded away to the point of leaking through.  This is the gunked up head. The purpose and message for this thread is how regular cooling system maintenance every year or at least every other year, to include flushing and re-filling for $50 a pop might have saved me a whopping $1000.00 repair bill. Sadly, I thought I was taking adequate care of my cooling system. The problem is poor circulation in this section of the cooling system, the gunk has no place to go, so it accumulates in the back of the head. I don't think the gunk caused the corrosion, the corrosion is acid etching or eating the Aluminum and/or Electrolysis.  This is the other side head with most of the gunk removed. Do yourself a favor and flush your system so you don’t end up like me. This engine has actually been flushed numerous times. Embarrassed? You bet! But not too proud to share and help. If you haven’t flushed your system in a year or two, this could happen to you!  I actually knocked the plug patch out for the purposes of taking pictures for this thread. As I stated, this manifold is scrap. I knew I was on borrowed time. This type of temporary patch should never be used as a permanent fix.  Electrolysis is kinda like Static Electricity only in water, and as you can see in the warning, it can cause failures, but not just in heater cores, it can attack any part of the cooling system that is metal. Here is an Instruction Warning Sheet on how to test for electrolysis on your vehicle. Sadly, I also lost my heater core a few years ago. The warning signs were there, but I never knew about Electrolysis in an automotive cooling system. If you have lost a heater core, I can't stress doing this test strongly enough. But don't wait or think that everything is o.k. if your Heater Core is still good, this test is too simple. DVOM's (Digital Volt Ohm Meter) are not that expensive $25-$30 low-end range. Borrow or rent one if you have to.

__________________

"If everyone is thinking alike, then no one is thinking". - Gen. George S. Patton Jr. Last edited by Rick Norwood; 11-17-2012 at 01:28 PM. |

|

|

|

|

|

|

#2 | |

|

AF Enthusiast

Join Date: Mar 2008

Location: garner, North Carolina

Posts: 3,579

Thanks: 86

Thanked 100 Times in 100 Posts

|

Re: OMG Coolant System Corrosion w/Pics!

Thanks for this Thread!

Are you going with Prestone extended life this time? Add a boost of Prestone Treatment once a year until a scheduled coolant flush +change. Last edited by danielsatur; 10-26-2012 at 11:14 AM. |

|

|

|

|

|

|

#3 | |

|

Big Tall Dumb Ass

Thread starter

Join Date: Dec 2003

Location: Deep Dark Doo-Doo

Posts: 1,304

Thanks: 15

Thanked 27 Times in 26 Posts

|

Re: OMG Coolant System Corrosion w/Pics!

Probably, but truthfully, I haven't bought anything yet. I have Green in it now because that is what I had in it when this whole thing went down. I have made a vow to flush this system every year. It is too easy and cheap rather than have to eat a giant repair bill.

__________________

"If everyone is thinking alike, then no one is thinking". - Gen. George S. Patton Jr. |

|

|

|

|

|

|

#4 | |

|

Advisor/Moderator

Join Date: Nov 2005

Location: Belleville, Michigan

Posts: 5,184

Thanks: 6

Thanked 103 Times in 95 Posts

|

Re: OMG Coolant System Corrosion w/Pics!

Good information and a great job putting it together! If it doesn't have pictures, it ain't worth a toot! Stickied

__________________

You have to know how it works, to figure out why it doesn't. |

|

|

|

|

|

|

#5 | |

|

AF Enthusiast

Join Date: Mar 2008

Location: garner, North Carolina

Posts: 3,579

Thanks: 86

Thanked 100 Times in 100 Posts

|

Re: OMG Coolant System Corrosion w/Pics!

Neglected coolant service is a type of cancer to your engine, your contaminated rusty coolant will cause an erosion effect on your Intake, head, block, water pump, and galvanized freeze plugs.

Picture a river rock in a river bed with rushing water, sand, and mud during storms. Last edited by danielsatur; 10-26-2012 at 12:43 PM. |

|

|

|

|

|

|

#6 | ||

|

Big Tall Dumb Ass

Thread starter

Join Date: Dec 2003

Location: Deep Dark Doo-Doo

Posts: 1,304

Thanks: 15

Thanked 27 Times in 26 Posts

|

Re: OMG Coolant System Corrosion w/Pics!

Quote:

__________________

"If everyone is thinking alike, then no one is thinking". - Gen. George S. Patton Jr. Last edited by Rick Norwood; 10-26-2012 at 05:18 PM. |

||

|

|

|

|

|

#7 | |

|

Big Tall Dumb Ass

Thread starter

Join Date: Dec 2003

Location: Deep Dark Doo-Doo

Posts: 1,304

Thanks: 15

Thanked 27 Times in 26 Posts

|

Re: OMG Coolant System Corrosion w/Pics!

Electrolysis testing is a simple as this. With the engine running and at operating temperature, Turn the selector on the DVOM to DC Volts (My DVOM is set for 20 DC Volts in this pic). The Negative (Black) lead goes to the Negative Battery terminal, (Lower Left of picture) and the Positive (Red) lead goes into the Soup. The Red lead does not touch anything inside the Radiator, only the Antifreeze. The meter does jump around a little bit, but as you can see, .5 volts exceeds the warning posted above. Follow the directions above especially about warming the engine to normal operating temperature, and make sure your coolant is good and mixed up. Don't try to test immediately after adding water. If your reading is high like mine, clean all your ground cables going from the battery to the engine block, frame, firewall etc. and retest. I did exactly that and my reading went to .25. Good luck and I sure hope this prevents someone from having a huge repair bill like mine. Let's not talk about the color of my Soup! LOL.

__________________

"If everyone is thinking alike, then no one is thinking". - Gen. George S. Patton Jr. Last edited by Rick Norwood; 11-17-2012 at 01:40 PM. |

|

|

|

|

|

|

POST REPLY TO THIS THREAD |

|

|

|