|

| Search | Car Forums | Gallery | Articles | Helper | AF 350Z | IgorSushko.com | Corporate |

|

| Latest | 0 Rplys |

|

|||||||

| Car Modeling Share your passion for car modeling here! Includes sub-forum for "in progress" and "completed" vehicles. |

|

Show Printable Version | Show Printable Version |  Email this Page | Email this Page |  Subscribe to this Thread

Subscribe to this Thread

|

|

|

Thread Tools |

|

|

#1 | |

|

AF Enthusiast

|

Resin Casting Part II Making the part

edit by jay: in case you missed part I: Resin Casting Part I - Making the mold

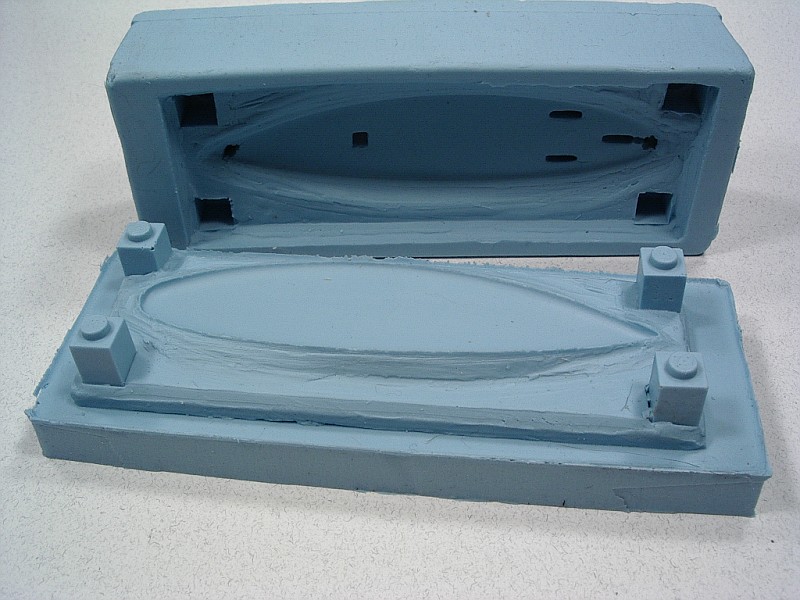

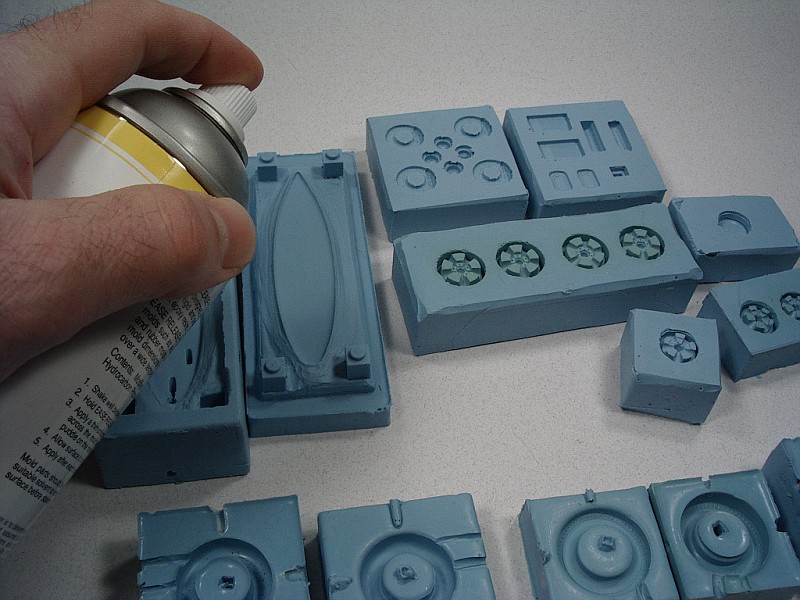

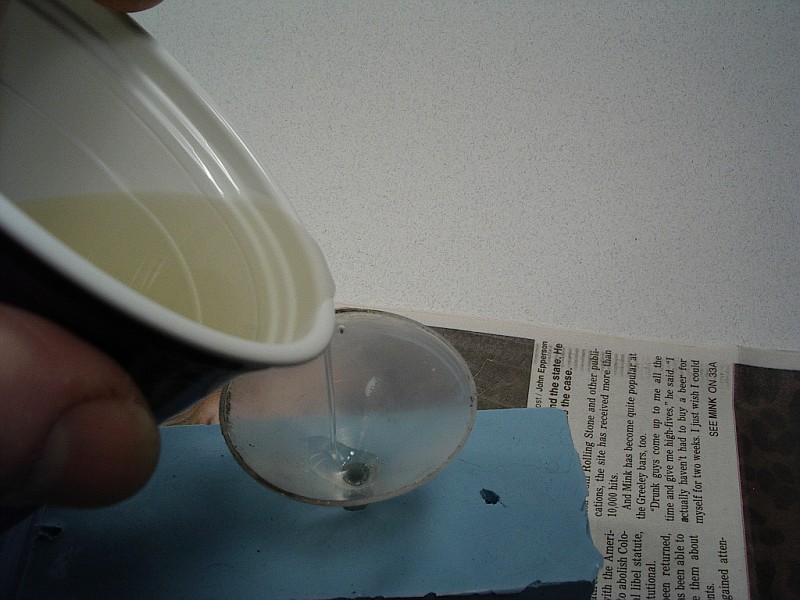

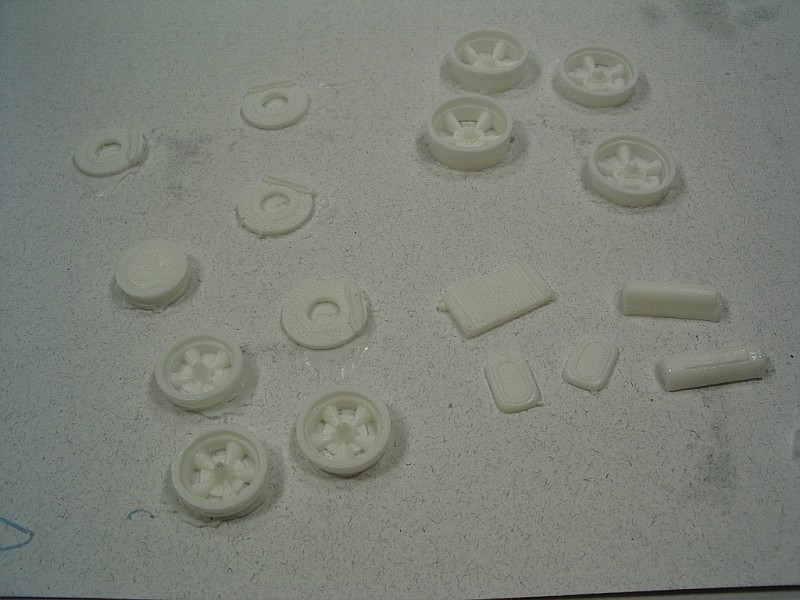

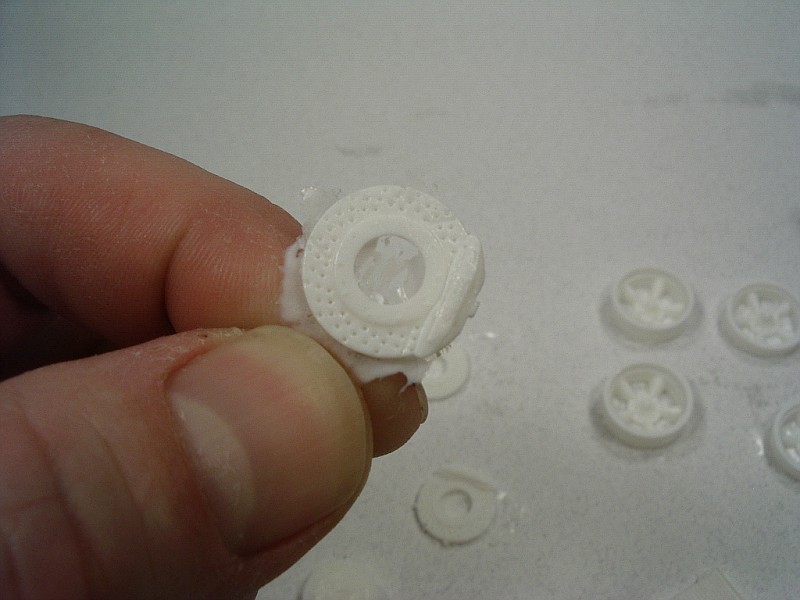

Okay folks as promised Part II In Part I we discussed making the mold. 1 piece flat molds are pretty easy. For multiple piece molds you need to think about how the mold will come apart to allow the master and subsequent cast parts to be removed. Don't follow me? Take a look at a kit body for example. Those unsightly seams we all have to sand off are actually mold lines where the pieces of a mold meet. Now visualize all the pieces that would be required. Another thing about multi piece molds is that you need a way to pour the resin in and a way for the air it displaces to get out ( vent ) otherwise you will have huge air pockets in the finished piece. Lets look at the 2 piece tire mold I made. Remember the nails that held it in place while I poured the first half? I left 2 in when I did the second half and now its time to enlarge the holes they left and clean them up a bit.Carefully cut the groove wider with an Exacto  When the halves are rejoined they should look like this  Now that that is ready a few more words on mulit piece molds. Sometiems even with a 2 piece you need a way to hold the piece up while Part 1 is poured, for this surfboard I made a 1/4 thick slab of clay on my glass and buried and blended the surfboard into it right up to the part ( halfway ) line.I poured the first half then turned the piece over, removed the clay added a few more legos to make the form deeper and then poured the second half.As you can see I also used a few small Legos as keys to hold the 2 halves together  If you want to learn more about multi piece molds I suggest you do some research into sculpture techniques and so on, theres way more than I can cover here. Allright time to pour. The same rules apply here, clean work area, clean molds, air bubbles are your enemy. Oh wait did I mention air bubbles are bad?!? LOL Prep all of your molds, check for dirt, stray bits of RTV, Cat hairs ...... You don't wnat anything to mess up your part. Now its time to add the mold release. Careful not too much, if it puddles it willl create a pocket in your completed part. And as always spray in a well ventilated area and use a mask. I should point out DO NOT DO THIS ANYWHERE NEAR YOUR PAINTING AREA!!!!!m Airborne silicone spray particles in your paint area will really screw up a good paint job.  I like to hold the 2 piecers together with a few rubber bands, not too tight you don't want to distort the mold  I am currrently using a 1 to 1 thin clear resin ( cures white ) that sets in about 40 minutes. Again accuracy is the key, if it says 1 to 1 it means 1 to 1. Pour equal amounts in seperate containers and then combine in a third. Gently mix with a craft stick and avoid introducing any air into the mix.It should be poured in a thin stream just like the RTV, remember this helps to eliminate any smalll air bubbles. If any do occur-such as this wheel that seems prone to air pockets in the center cap- I found you can use a big straight pin to coax it to the surface  As you can see I overfill the one piece flat molds slightly. Then I take a credit card ( save the fakes that come in the mail with all those annoying credit card offers ) and gently scrape off the excess leaving a nice clean flat back   For multi piece molds I like to use a tiny funnel to direct the resin into the hole  Fill until the excess comes out the vent hole(s)  Sit back and wait, this is where the patience comes into play. Soon you will notice the resin begin to kick and turn slightly white   a little more but not quite cured   When it turns completely white its almost done. Just to be safe wait another 10 or 15 minutes because if its still warm from the curing action when you remove the part it can warp.  Tired of wating? Gently demold.  Big Brakes anyone? The light flashing can easily be sanded off  Did you say slicks ?  There you have it, now its time to clean em up and paint em. You will need toi remove the mold release, I do this by washing several times in a degreasing dish soap. You may have some very thin flash on the back of the pieces from the 1 piece flat molds, this can happen when you scrape the excess resin. Its easily taken off by sanding the back of the piece on a flat surface. Fill any pinholes with putty ( I use Bondo Glazing Putty ) Sand any seams flat. Follow your normal painting steps. I have been thinking that since the tires are cast in white I could paint them the correct shade of black and then sand back through to the white where the lettering is. Hopefully producing a nice tire with raised white lettering. Peace and Good Luck Dag Last edited by dag65; 04-25-2011 at 06:27 PM. Reason: link back to part I |

|

|

|

|

|

|

#2 | |

|

AF Enthusiast

|

Re: Resin Casting Part II Making the part

Thanks for sharing this with us!

Great work!  |

|

|

|

|

|

|

#3 | |

|

AF Enthusiast

|

how did you make the molds?? It looks very nice

__________________

Failure is only the opportunity to begin again more intelligently.

|

|

|

|

|

|

|

#4 | |

|

AF Enthusiast

|

nvm about the question. it looks great,makes me wana do it myself!!

__________________

Failure is only the opportunity to begin again more intelligently.

|

|

|

|

|

|

|

#5 | |

|

AF Enthusiast

|

Re: Resin Casting Part II Making the part

This is a F*cken tight ass how to DAG65 now i can mold seats and wheels. Im going to get all of the supplies tommorow and start making seats, Wheels, Brembo Brakes and Engine parts

__________________

"Joy Wouldn't feel so good if it wasn't for Pain" - 50 Cent "Death gotta be easy cause life is hard it'll leave you physically mentaly scarred." - 50 Cent  Mines Nissan Skyline GT-R (R34) |

|

|

|

|

|

|

#6 | |

|

AF Fanatic

|

Re: Resin Casting Part II Making the part

really well made.. Hope this one found id way to the FAQ..

__________________

CarsModeling.com. My Scale Model Cars blog. |

|

|

|

|

|

|

#7 | |

|

AF Enthusiast

|

Re: Resin Casting Part II Making the part

man..40 minutes to cure??? the resin i use cures in 10..and it's the thin clear/white stuff.

|

|

|

|

|

|

|

#8 | ||

|

AF Enthusiast

|

Re: Re: Resin Casting Part II Making the part

Quote:

__________________

Failure is only the opportunity to begin again more intelligently.

|

||

|

|

|

|

|

#9 | |

|

AF Enthusiast

Join Date: Mar 2002

Posts: 2,466

Thanks: 33

Thanked 21 Times in 20 Posts

|

Re: Resin Casting Part II Making the part

this will help thanks i always wonders bout that

__________________

|

|

|

|

|

|

|

#10 | |

|

AF Enthusiast

|

Re: Resin Casting Part II Making the part

nice it will be very usefull!

|

|

|

|

|

|

|

#11 | |

|

AF Enthusiast

Join Date: May 2003

Location: Dortmund

Posts: 960

Thanks: 32

Thanked 77 Times in 52 Posts

|

__________________

Julian |

|

|

|

|

|

|

#12 | |

|

AF Enthusiast

Join Date: Nov 2003

Location: Soisy sur Seine

Posts: 994

Thanks: 0

Thanked 1 Time in 1 Post

|

Re: Resin Casting Part II Making the part

Thanks! Thanks! Thanks! Thanks! Thanks! Thanks!

__________________

Back to life soon...

|

|

|

|

|

|

|

#13 | |

|

AF Enthusiast

|

Great tutorial.Plan on using it.

|

|

|

|

|

|

|

#14 | ||

|

AF Enthusiast

Thread starter

|

Re: Re: Resin Casting Part II Making the part

Quote:

|

||

|

|

|

|

|

#15 | |

|

AF Regular

Join Date: Feb 2004

Location: Sacramento, California

Posts: 74

Thanks: 0

Thanked 0 Times in 0 Posts

|

Re: Resin Casting Part II Making the part

Great tutorial, I was at the store today talking about casting and the tech told me that you can cast urethane for rubber like tires, and you can tint it black.

|

|

|

|

|

| ||||||||||||||||||||||||||||||||||||||

|

POST REPLY TO THIS THREAD |

|

|

|