|

| Search | Car Forums | Gallery | Articles | Helper | AF 350Z | IgorSushko.com | Corporate |

|

| Latest | 0 Rplys |

|

|

#16 | |

|

Resident Chemist

|

Re: 4Runner FAQs

Tacoma/4Runner Differential References

Thanks to Flash75 for the following information: This links covers differential information for most Toyota truck applications. If covers ratios and how to determine your ratio, the various types of differentials and their applications. Also covered are axle widths and Toyota electric locking differentials. http://home.4x4wire.com/erik/diffs/ Here are instructions for changing and setting up Toyota gears. The information should apply to all Toyota trucks. Great information for those who wish to change their gears. http://www.4x4wire.com/toyota/tech/gear_setup/ Tire Size and Gear Ratio Chart It lists the best combination for near stock, fuel economy and performance. http://toyota.off-road.com/toyota/article/articleDetail.jsp?id=186404

__________________

Forum Guidelines:http://www.automotiveforums.com/vbulletin/guidelines.html "What we've got here is a failure to communicate" |

|

|

|

|

|

#17 | |

|

Resident Chemist

|

Re: 4Runner FAQs

Good Exhaust System Information

http://www.nsxprime.com/FAQ/Miscellaneous/exhausttheory.htm Thanks to Flash75

__________________

Forum Guidelines:http://www.automotiveforums.com/vbulletin/guidelines.html "What we've got here is a failure to communicate" |

|

|

|

|

|

#18 | |

|

Resident Chemist

|

Re: 4Runner FAQs

Bleeding Brakes

How to bleed brakes. Link covers Toyota pickups and 4Runners. http://www.4x4wire.com/toyota/maintenance/bleedingbrakes/ Thanks to Flash75

__________________

Forum Guidelines:http://www.automotiveforums.com/vbulletin/guidelines.html "What we've got here is a failure to communicate" |

|

|

|

|

|

#19 | |

|

Resident Chemist

|

Re: 4Runner FAQs

TECHNICAL ARTICLES ON TOYOTA ENGINE SYSTEMS

EXTENSIVE AUTOMOTIVE INFORMATION LINKS Q: Where can I find technical information on my EGR system? I want to modify it and I'd better understand what's going on there first.  A: A good source of technical articles and automotive information links is Kevin Sullivan's Autoshop 101 site: http://www.autoshop101.com/ Here are the titles of his technical articles followed by direct links to the articles: Technical Articles Toyota Series - Electrical Electrical Fundamentals with questions.pdf http://www.autoshop101.com/forms/h1.pdf Electrical Circuits with questions.pdf http://www.autoshop101.com/forms/h2.pdf Electrical Components with questions.pdf http://www.autoshop101.com/forms/h3.pdf Analog vs Digital Meters with questions.pdf http://www.autoshop101.com/forms/h4.pdf Wire, Terminal and Connector Repair w/qu.pdf http://www.autoshop101.com/forms/h5.pdf Automotive Batteries with questions.pdf http://www.autoshop101.com/forms/h6.pdf Toyota Starting Systems with questions.pdf http://www.autoshop101.com/forms/h7.pdf Toyota Charging Systems with questions.pdf http://www.autoshop101.com/forms/h8.pdf Understanding Toyota Wiring Diagram.pdf http://www.autoshop101.com/forms/h09e.pdf Electrical Diagnostic Tools.pdf http://www.autoshop101.com/forms/h10e.pdf Diagnosing Body Electrical Problems.pdf http://www.autoshop101.com/forms/h11e.pdf Semiconductors with questions.pdf http://www.autoshop101.com/forms/h12.pdf Transistors with questions.pdf http://www.autoshop101.com/forms/h13.pdf Computers / Logic Gates with questions.pdf http://www.autoshop101.com/forms/h14.pdf Overview of Sensors & Actuators w/quest.pdf http://www.autoshop101.com/forms/h15.pdf Electronic Transmission #1 - Operation.pdf http://www.autoshop101.com/forms/h16.pdf Electronic Transmission #2 - Diagnosis w/quest.pdf http://www.autoshop101.com/forms/h17.pdf Shift Interlock System.pdf http://www.autoshop101.com/forms/h18.pdf Technical Articles Toyota Series - Engine Performance OBDI (pre-1996 5S-FE and pre-1994 V6) EFI#1 EFI System Overview.pdf http://www.autoshop101.com/forms/h20.pdf EFI#2 Air Induction System.pdf http://www.autoshop101.com/forms/h21.pdf EFI#3 Fuel Delivery & Injection Controls.pdf http://www.autoshop101.com/forms/h22.pdf EFI#4 Ignition System.pdf http://www.autoshop101.com/forms/h23.pdf Engine Controls #1 - Input Sensors.pdf http://www.autoshop101.com/forms/h24.pdf Engine Controls #2 - ECU/Outputs.pdf http://www.autoshop101.com/forms/h25.pdf Engine Controls #3 - Idle Speed Control.pdf http://www.autoshop101.com/forms/h26.pdf Engine Controls #4 - Diagnosis.pdf http://www.autoshop101.com/forms/h27.pdf Technical Articles Toyota Series - Engine Performance OBD-II (1996 and newer 5S-FE, and '94 and newer 1MZ-FE) Sensors#1 - Mode Sensors and Switches.pdf http://www.autoshop101.com/forms/h31.pdf Sensors#2 - Thermistors with questions.pdf http://www.autoshop101.com/forms/h32.pdf Sensors#3 - Position Sensors with questions.pdf http://www.autoshop101.com/forms/h33.pdf Sensors#4 - Air Flow Sensors with questions.pdf http://www.autoshop101.com/forms/h34.pdf Sensors#5 - Pressure Sensors with questions.pdf http://www.autoshop101.com/forms/h35.pdf Sensors#6 - Speed Sensors with questions.pdf http://www.autoshop101.com/forms/h36.pdf Sensors#6 - Oxygen / Air Fuel Sensors w/ques.pdf http://www.autoshop101.com/forms/h37.pdf Sensors#8 - Knock Sensors with questions.pdf http://www.autoshop101.com/forms/h38.pdf Ignition#1 - Ignition Overview w/questions.pdf http://www.autoshop101.com/forms/h39.pdf Ignition#2 - Electronic Spark Advance w/quest.pdf http://www.autoshop101.com/forms/h40.pdf Ignition#3 - Distributor / Distributorless w/qu.pdf http://www.autoshop101.com/forms/h41.pdf Fuel System#1 - Overview with questions.pdf http://www.autoshop101.com/forms/h42.pdf Fuel System#2 - Injection Duration w/ques.pdf http://www.autoshop101.com/forms/h43.pdf Fuel System#3 - Closed Loop /Fuel Trim w/qu.pdf http://www.autoshop101.com/forms/h44.pdf OBDII#1 - Overview of On-Board Diagnostics.pdf http://www.autoshop101.com/forms/h46.pdf OBDII#2 - Serial Data.pdf http://www.autoshop101.com/forms/h47.pdf OBDII#3 - Data Interpretation.pdf http://www.autoshop101.com/forms/h48.pdf Emission#1 - Chemistry of Combustion.pdf http://www.autoshop101.com/forms/h55.pdf Emission#2 - Emission Analysis.pdf http://www.autoshop101.com/forms/h56.pdf Emission#3 - Engine Sub Systems.pdf http://www.autoshop101.com/forms/h57.pdf Emission#4 - Closed Loop Feedback Systems.pdf http://www.autoshop101.com/forms/h58.pdf Emission#5 - Electronic Spark Advance.pdf http://www.autoshop101.com/forms/h59.pdf Emission#6 - Idle Speed Control Systems.pdf http://www.autoshop101.com/forms/h60.pdf Emission#7 - Exhause Gas Recirculation.pdf http://www.autoshop101.com/forms/h61.pdf Emission#8 - Evaporative Emission Control.pdf http://www.autoshop101.com/forms/h62.pdf Emission#9 - Positive Crankcase Ventilation.pdf http://www.autoshop101.com/forms/h63.pdf Emission#10 - Catalytic Converter.pdf http://www.autoshop101.com/forms/h64.pdf Emission#11 - Secondary Air.pdf http://www.autoshop101.com/forms/h65.pdf Don't ignore the information and links in the "Automotive Links" section. Also, the "Online Bookstore" is useful if you want to get ASE certified.

__________________

Forum Guidelines:http://www.automotiveforums.com/vbulletin/guidelines.html "What we've got here is a failure to communicate" |

|

|

|

|

|

#20 | |

|

Resident Chemist

|

Re: 4Runner FAQs

STARTER CLICKS ONCE BUT DOES NOT TURN ENGINE

Q: Often my starter will just click and not turn over the engine. It will do this for a long time, but eventually it will act normally. Is this a common problem with Toyotas? How can I fix it? A: Yes, it is a common problem with Toyota starters. Many times, the problem is sticking starter solenoid contacts. See the following links for descriptions on how to replace them. This is a really cheap and easy fix on a Tacoma and should be the first thing you try after you check all the cable connections and the battery quality. http://www.automotiveforums.com/vbul...d.php?t=166530 15 Toyota (NipponDenso now called Denso) starter-repair reference sites: http://www.4crawler.com/4x4/CheapTricks/Starter.shtml http://char.tuiasi.ro/vw/reality/rog...s/Starter.html http://yotarepair.com/startercontacts.html http://www.toyotaoffroad.net/afertig...rterrepair.htm http://www.4x4wire.com/toyota/maintenance/starter/ http://www.yotatech.com/~corey/tech/...r/haveblue.htm http://www.sleeoffroad.com/technical...er_rebuild.htm http://www.startercontacts.com/install.htm http://www.startercontacts.com/image...ded%20view.jpg http://www.colorado4x4.net/tech/star..._contacts.html http://www.barneymc.com/toy_root/techneek/starter.htm http://perso.wanadoo.fr/adherence.4x4/start_bj.htm http://www.automotiveforums.com/vbul...d.php?t=166530 http://www.toyotanation.com/forum/sh...312&forumid=10 http://www.toyotanation.com/showthre...312&forumid=10 Starter contact kits (8mm ID hole): Ace Electric # S-5263 (only two contacts) Ace Electric # S-5264 (only two contacts) Metro # 66-82104 (only two contacts) (www.metroautoinc.com ,Pomona,California) Toyota # 28226-72010/80 (battery side)(also1KZTE-2LT-1KZT) Toyota # 28226-72080 (8808-9108) Toyota # 28226-16130 (9108-9308) Toyota # 28226-55050 (9308-9511) Toyota # 28226-70040 (9308-9511) Toyota # 28226-72040 (motor side if needed) Toyota # 28226-72010 (8808-9511) Toyota # 28226-74070 (9108-9511) For others besides 22R series: Toyota # 28226-54220 (motor side) (2LTE, 3L..LN13# IKZTE, 2L#, KZN130,LN108,112,85..4FC) Toyota # 28226-54250 (Diesel Surf 2.4TD, contains a new end cover and gasket) Toyota # 28226-54320 (battery side) (2LTE, 3L..LN13# IKZTE, 2L#, KZN130, LN108,112,85..4FC,3B-1HZ-BJ73-HZJ7#-1KZT-KZJ70) Toyota # 28226-17030 (battery side) (1H#-HDJ80-HZJ80) Toyota # 28226-56250 (battery side) (3B-1HZ-1PZ-PZJ7#) Starter contacts only (8mm ID hole): Ace Electric # S-5231 Ace Electric # S-5293 (crescent moon shape) Ace Electric # S-5295 (crescent moon shape) Metro # 66-82106 (www.metroautoinc.com ,Pomona,California) Tons more at: http://www.metroautoinc.com/PDF%20Fi...%20Contact.pdf Toyota # 28226-70040 Wilson’s Electric # 45-29-652 Starter brushes: AC Delco # D762 GP Sorensen # 255048 Standard # JX-117 Whether your starter uses two rectangular types or one rectangular and one crescent you can substitute with two squares or one square and one crescent so any of the above part #'s for those kits will be the right ones, or about half of the auto electric shops in your local yellow pages would sell aftermarket contacts for only $5 each or the pair. Thanks to SydneyCanada for the above information STARTER CLICKS CONTINUOUSLY BUT DOES NOT TURN ENGINE Q: What if the starter clicks not once, but very fast and does not turn the engine over? A:The problem you're having is not the solenoid contacts as described above. With bad solenoid contacts, there is only one click (the starter relay), not many. Your problem is insufficient current/voltage getting to the starter. Most likely cause is a bad battery. Before you buy one, check the battery terminals - make sure they are on tight and they are clean. Check the connections on the other end of the battery cables for tightness and cleanliness also. If all looks good, replace the battery. If the battery cable connections are bad, loosen them from the battery and clean them with baking soda/water slurry until they are bright metal, then reconnect them and tighten them snug. Coat them with petroleum jelly to prevent them from corrosion. It it's possible something has been left on, like your headlights or dome light etc. and the battery may be drained/discharged, try charging it first or bring it in to have it tested before you buy a new one. BLOWER MOTOR FOR HEATER OR A/C DOES NOT WORK ON ALL SPEEDS Q: My blower motor doesn't work for the bottom three speeds. What is the problem - is it the motor or what? A: It is most likely a bad connection or bad resistor on the resistor block that controls the current to the motor. See the discussion in the following links: http://www.automotiveforums.com/vbul...d.php?t=252829 http://www.4crawler.com/4x4/CheapTricks/Blower.shtml

__________________

Forum Guidelines:http://www.automotiveforums.com/vbulletin/guidelines.html "What we've got here is a failure to communicate" Last edited by Brian R.; 05-16-2010 at 02:51 PM. |

|

|

|

|

|

#21 | |

|

Resident Chemist

|

Re: 4Runner FAQs

Thanks to yotarepair.com for alternative instuctional drawings:

TIMING BELT REPLACEMENT INSTRUCTIONS Q: My engine stopper running suddenly on the highway and now it won't start. Any guesses as to what the problem is? How do I replace my timing belt? What should I replace while I'm in there to save time in the future? A: It sounds like you may have broken your timing belt. If you can see the cam shafts by looking through the oil filler hole in the head cover, then you can use these as an indicator. If the cams don't turn when the engine is cranked, your timing belt is broken. You may have to remove the valve cover. Here are links to instructions for replacing the timing belt in various Tacoma engines: 2RZ-FE Timing Chain 3RZ-FE Timing Chain 5VZ-FE http://yotarepair.com/PDF%20files/5V..._belt_remo.pdf http://yotarepair.com/PDF%20files/5V..._belt_inst.pdf Another procedure: http://www.4x4wire.com/toyota/maintenance/timing_belt/ Additional Comments on Replacing Timing Belts Other than the timing belt whether or not you need more parts depends on if there are any fluid leaks inside the timing cover, the water pump may need to be replaced and there may be oil seals such as the front crankshaft seal or the camshaft seals that may be leaking and need to be replaced. If you do it yourself, make sure you understand how to set #1 piston at TDC on compression stroke. Also, be prepared to stop and put everything back together if you find you cannot remove the crank pulley bolt. I think this is the hardest part from a strength point of view. Air gun is best way. Really long cheater bar with tool to hold the crank is also good. A method of last resort is to position the breaker bar handle on the driver's side frame rail and just tap the starter with the plugs out. If the breaker bar handle is secure, the bolt will loosen. Don't use this method to completely back out the bolt, just to break it loose. Also, be careful and gentle with the new timing belt. Handle it as if it were a piece of gold foil. Don't bend it sharply, contaminate it with anything, or turn it inside out. Don't scratch the sensor part of the crankshaft timing pulley. Don't use the timing belt tension to tighten the mounting bolt of the camshaft timing pulley. If there is noticeable wear or cracks on the belt face, check to see if there are nicks on the side of the idler pulley lock. If there is wear or damage on only one side of the belt, check the belt guide and alignment of each pulley. If there is noticable wear on the belt teeth, check the timing cover for damage, correct gasket installation, and for foreign material on the pulley teeth. Check to make sure the idler pulley turns smoothly. If not, replace. Clean all the pulleys and keep them clean. If you have to turn the crankshaft, always turn it clockwise. Make sure you have all the gaskets you need. Clean the gasket surfaces to shiny metal everywhere before you replace the gaskets. Replace the timing cover gaskets if they are at all questionable. Make note of all the electical connections you disconnect when you disconnect them. Make sure they are all connected when you are done (DOH!). Check the accessory drive belts and replace them if they are old. Torque everything. INTERFERENCE ENGINES Q: What is an interference engine and is my Toyota engine an interference engine? Why should I care? A: An interference engine is one in which the valves and pistons can touch if the cams and crank are not kept in correct timing by the timing belt or chain. Most (not all) Toyota passenger car engines are free-running (non-interference engines). This means that if your timing belt breaks, then all that will happen is your engine will not run anymore until the belt is replaced. In an interference engine, piston-to-valve contact will cause very serious damage to the engine if the timing belt breaks. To see if your engine is an interference engine or not, look it up in the following brochure: http://www.gates.com/downloads/downl...older=brochure An asterisk opposite your engine means it is an interference engine.

__________________

Forum Guidelines:http://www.automotiveforums.com/vbulletin/guidelines.html "What we've got here is a failure to communicate" |

|

|

|

|

|

#22 | |

|

Resident Chemist

|

Re: 4Runner FAQs

SERVICE PUBLICATIONS

Q: Where can I purchase Toyota Service and Repair Manuals for my Tacoma? A: Printed copies of all Toyota, Scion, and Lexus service support information can be purchased directly from the Toyota Materials Distribution Center or MDC. The MDC stocks printed versions of most Toyota service information products, including legacy model information that is not available on this site. Note: Certain inventory items are produced in limited quantities and may not be reprinted or reissued once initial inventory is depleted. MDC telephone operators accept Visa and MasterCard credit card orders, Monday through Friday, 8 AM to 5 PM Pacific Time. To place orders call 1-800-622-2033 VARIOUS USED MANUALS - mostly older http://www.autobooksonline.com/ TRANSMISSION REPAIR MANUALS Q: Where can I purchase transmission repair manuals? A: http://www.autorepairmanuals.biz/sit...83/page/267592 RENT ONLINE ACCESS TO MANUALS HERE: http://www.eautorepair.net/ http://www.alldata.com/products/diy/index.html

__________________

Forum Guidelines:http://www.automotiveforums.com/vbulletin/guidelines.html "What we've got here is a failure to communicate" |

|

|

|

|

|

#23 | |

|

Resident Chemist

|

Re: 4Runner FAQs

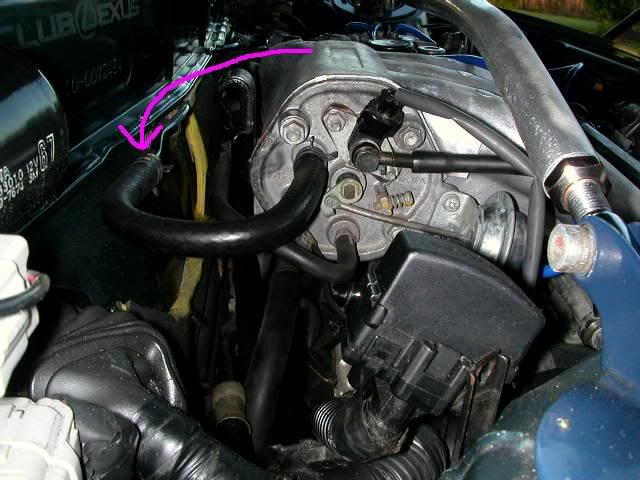

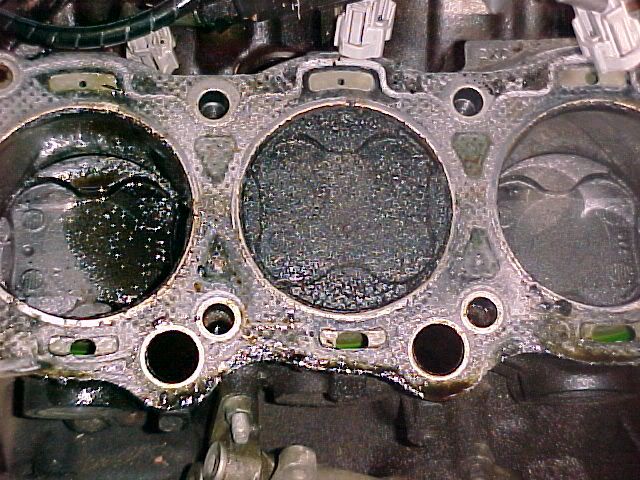

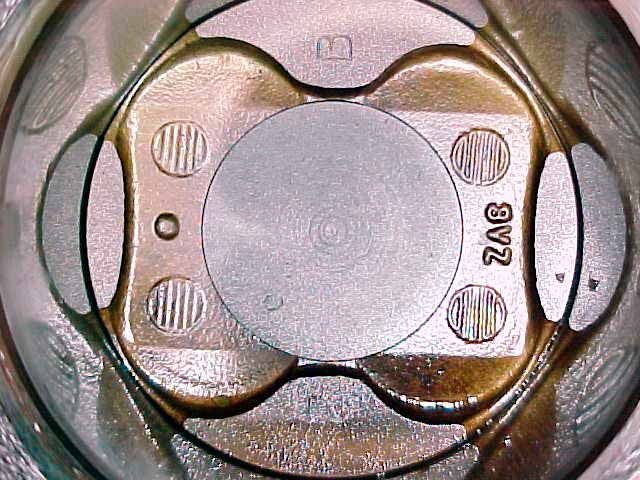

HOW TO ADMINISTER SEAFOAM TO CLEAN YOUR ENGINE

(Thanks to Toysrme for the following discussion) Seafoam makes the world go round! Not really, but at $5 a can it's a steal. A can is 1 pint.  You need 2 cans. Pour 1/2 a can in the gas tank when you stop to fill up. (This ensures it mixes well) Pour the other 1/2 in with fresh engine oil. At the least you will notice that the engine will idle noticeably smoother. Here's where most people get confused. Using it down the intake to clean the combustion chamber & parts of the head. 1) Drive the car around the block until it comes up to temp 2) Pour 1/3 of a can into a separate container (1/4 of a can for 4 cylinders) 3) Crank the engine 4) Pull the brake booster hose off & put your finger over the end so the car doesn't lean out & stall.  5) Drop the hose in the bottom of the container & let your finger off the end. If the engine doesn't stall out completely SHUT IT OFF ASAP. The fluid will near instantly disappear & the engine should stall from being too rich to run, or being too lean from the hose letting air in afterwards. This will not break your engine. You're not using enough fluid to hydrolock it. 6) The engine should sit for 5 min. 7) Crank the engine & let it run until the smoke dies down Normally you will get an ungodly amount of smoke. 8) As the smoke dies down, drive the car around. Be sure to make liberal use of 1st & 2nd gear to get to the higher portions of the RPM range a few times. That would be 5000-6850rpm.. You are not breaking your engine by running it at those rpm... All of the computers on all of the engines will cut the fuel to slow the RPM down before the engine is damaged. Yes, they are built for it... Why someone would want to do this? To clean gunk, sludge, & misc. heavy buildup out of the oil system. Pump, passages, bearings, walls. To clean the fuel system. To clean carbon out of the combustion chamber. Now some people ask why you want to go to the trouble of cleaning carbon out of the engine. Because as it builds up on the valves, they don't seal as well - causing poor compression while the leaking gas superheats parts of the engine that are not designed for it. Because carbon in the combustion chamber is bad. mmmm kay? Any carbon becomes superheated. Superheated carbon / metal will cause the incoming fuel & air to ignite earlier than it should be. This (Detonation, pinging, kocking - all just names for pre-ignition) is very derailment to many aspects of engine life. This is what a 3vz-fe looks like @ 95,000 miles. (Forget the fluids, fluids spill look at the black carbon build-up)  Here's what it looks like 6 months after the last 3 Seafoam treatments.  Seafoam = Good. It's cheap & versatile, while working at least as good as anything else; regardless of the cost. Brian R. note: GM Top Engine Cleaner is another useful additive for the above purpose.

__________________

Forum Guidelines:http://www.automotiveforums.com/vbulletin/guidelines.html "What we've got here is a failure to communicate" |

|

|

|

|

|

#24 | |

|

Resident Chemist

|

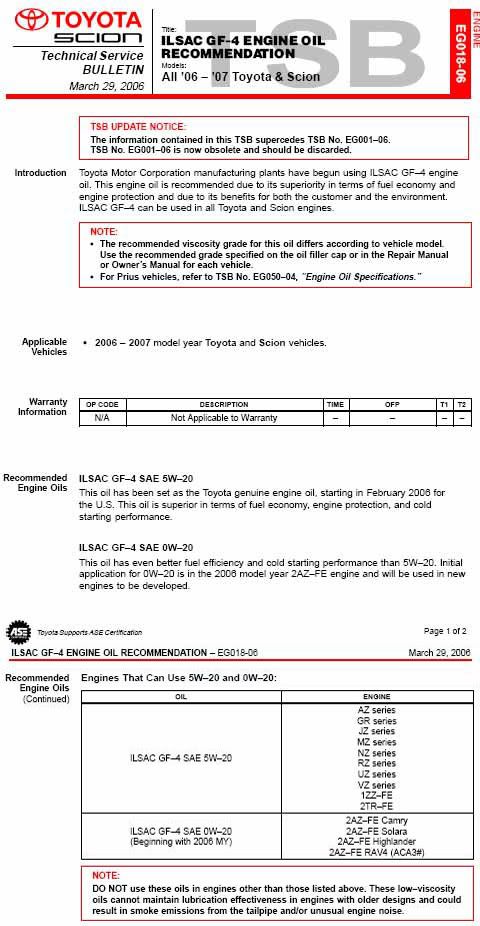

Toyota Approves Use of 0W-20 and 5W-20 GF-4 Oils

Toyota has approved the use of 5W20 GF-4 oils (e.g., Mobil1) in most modern engines, and 0W-20 in 2AZ-FE engines as shown in the folowing TSB.

I have been using the 5W-20 oil in my 5VZ-FE 4Runner engine for about 6 months now and can see the difference in mileage. It doesn't appear that either of these oils are approved for the 22R, 3S-FE or 5S-FE engine. I have been using a 50:50 mix of the 5W-20 and 5W-30 Mobil1 in my '96 5S-FE Camry for about 8k miles without any noticable problems. I have also notices a marked increase in mileage in this engine. I have been getting 410 miles/tank (about 27 mpg with 75:25 highway:city). I used to get around 360-375 miles per tank.

__________________

Forum Guidelines:http://www.automotiveforums.com/vbulletin/guidelines.html "What we've got here is a failure to communicate" Last edited by Brian R.; 08-18-2006 at 01:10 AM. |

|

|

|

|

|

#25 | |

|

Resident Chemist

|

Re: 4Runner FAQs

BUYING A CAR/TRUCK - WHAT TO LOOK FOR

Q: I'm about to purchase a mint vehicle, is there anything I should know about it before I purchase it. it only has 60k original miles. and great body. A: Timing belt may be due to be changed at 60K (or 90K), an added expense. Check the CV boots and see if they are torn - or grease has been thrown over the underbody in the area of the CV joints. Expensive repair. Check the color of the ATF. If it's really dirty, it may have never been changed and you may have a potential problem there. If it's mud, don't buy it. If it's just reddish brown, get it flushed as soon as you can. Make sure it shifts smoothly, quietly, and without a jerk. May indicate a problem. You should actually flush (not just drain & refill) all fluids ASAP after buying the car. Oil change, Transmission, Coolant, Brake lines, Powersteering fluid. Keep this expense in mind. Pull the oil filler cap and see if there is bright shiny metal visible or are there extensive black deposits, indicating a lack of maintenance. If there is alot of black crap visible, don't buy it. Check for oil leaks under the engine and transmission. Have the brakes checked and see if they need to be changed. That will be an added expense after you buy it. Tires are costlly also. Make sure there is no smoke or steam coming out of the exhaust, either when just starting it or after it is hot. May be a sign of having been overheated or other serious problem. Don't buy it. Check the coolant to make sure it is pretty red or green. No foam, bubbles in the overflow tank when the engine is running, or discoloration. If there are foam or bubbles - don't buy it. Engine should run smoothly and quietly, no jerking, hesitating, or "Check Engine" light showing. Check recent emissions results if available. Car should have no vibration at any speed. If there is any vibration, see if there is a bump in one of the tires. Anything else - don't buy it. If one of the tires has a bump, get it replaced as soon as possible. Take the cost of 4 tires into account if they are pretty used. You don't want one new tire on a set of badly used ones. On the test drive the vehicle should steer straight with no excessive side pull and the steering wheel should not be off center when driving on a straight road. Make allowances for an alignment and maybe front-end work if you find these indicators. Could be expensive. Bounce the car hard, front and back separately. If it doesn't stop bouncing immediately, you may need to buy a set of struts. This can be expensive. As a general rule, there should be nothing wrong with the struts at 60K. If the car is a relatively new model, it may indicate that the car has been abused (or the speedometer has been rolled back). If the car is really old, the struts may be shot due to age alone. Mileage is not the only indicator of the expected strut condition. An old car doesn't have to have been abused to have bad struts at low mileage. Along these lines: regardless of whether or not it has been driven hard, or sitting still, any car, regardless of make, can be expected to get around 10 years on the factory struts, springs, and rubber type mounts (i.e. strut mounts, bushings, engine mounts, etc.). And that it is fairly downhill quickly from there. Check under the car for shiny welds or a lot of new parts that may indicate the car has been extensively fixed because of a collision. Also check the dashboard and see if it has a VIN in front of the driver, no VIN number indicates it has been replaced - check the VIN against the title. Don't buy it if anything is wrong. Check the body panel fasteners. Example - Fender, Hood, Door, Trunk bolts, etc. Signs of chipped paint, disturbed mating surfaces, and tool usage may indicate that the vehicle has had body damage and been repaired. Run your fingers along the seams between the body panels. Wavyness or uneven spacing in the body panels indicates the presence of collision damage. Likewise, check the shock towers for welds, indicating repairs. Check all the lights, turn signals, cruise control (may be designed to work only above a certain speed), and other electrical components for proper operation. Also check that the air conditioning blows cold air and the heater works. If you don't know the car's history, check CARFAX.com for history. Only buy it if it has a squeeky clean history. There are other cars available that don't have potential serious problems. Don't take chances if there are unknown costs after the purchase. Don't buy it if there is any doubt about it's condition. Have a mechanic look at it - it is worth the money.

__________________

Forum Guidelines:http://www.automotiveforums.com/vbulletin/guidelines.html "What we've got here is a failure to communicate" Last edited by Brian R.; 08-13-2006 at 12:13 AM. |

|

|

|

|

|

#26 | |

|

Resident Chemist

|

Re: 4Runner FAQs

WHEEL BOLT PATTERN, LUG NUT THREAD SIZE, AND OFFSET

Q: I need some rims for the winter time and I came accross these. They came off a 06' Ford F150. They are 17's and the size he gave me was 6x135. Will they fit my '97 4Runner? A: No, the F-150 wheels won't fit. Not only do the bolt patterns have a different diameter, but the offset is wrong. F-150 6-135 and +44 offset 4Runner 6-139.7 and +08 offset Here is a link for any vehicle bolt pattern, thread size, and offset: http://www.racingdimension.com/RD_Wh...gnut_Chart.htm

__________________

Forum Guidelines:http://www.automotiveforums.com/vbulletin/guidelines.html "What we've got here is a failure to communicate" |

|

|

|

|

|

#27 | |

|

Resident Chemist

|

Re: 4Runner FAQs

TRANSMISSION FLUIDS

Q: My '94 4Runner is a little low in tranny fluid. I checked the book and it states using Dextron ll Automatic Tansmission Fluid. I have been to two different stores in the area and no one seems to have it. Is there another name that it goes by? What gives???? I even called the Toyota Dealer and he said that Dextron ll is the correct fluid for my '94 4Runner. What's going on? I feel as though I'm in a twilight zone!!!! I even checked Advance Auto online and there isn't a listing for it there either. Any help would be appreciated! A: You can use Dexron III anytime Dexron II was recommended. From Chevron.com: Maintaining Your Transmission These days there's no such thing as "normal" driving conditions. Heavy stop-and-go traffic, frequent short trips, trailer towing; they all put your engine to the supreme test and can take a toll on your transmission. Under these tough conditions, you can help your transmission run better and longer when you follow the vehicle manufacturer's severe service schedule and change the automatic transmission fluid at the recommended intervals (typically every 15,000 to 30,000 miles). Also, if you suspect that your ATF has oxidized or deteriorated between service intervals, you may want to consult with your local automotive service center. Selecting the proper quality of ATF is not as easy as it once was. In the past, ATF came in two types: DEXRON®, MERCON® or ATF Type F. However, as transmissions have become more advanced, automobile manufacturers have introduced fluids specifically designed for their transmissions. Always check your owner's manual for the required type of ATF. Here are the most commonly specified ATFs: DEXRON® -III This is a specification for General Motors vehicles, but many foreign manufactures specify a DEXRON approved ATF as well. DEXRON-III can be used in transmissions that call for DEXRON-IIE or DEXRON-II. MERCON® Most Ford vehicles manufactured between 1980 and 1999 specify a MERCON ATF. ATFs that meet DEXRON-III requirements usually meet the MERCON requirements as well. MERCON® V Beginning with the 1997 model year, Ford introduced a higher performance level ATF with the MERCON V specification. Many Ford automatic transmissions from 1999 on will require a MERCON V fluid. The most notable exceptions are the E40D, 4R100, and CD4E transmissions, which still specify regular MERCON ATF. Type F Type F is specifically designed for all pre-1977 Ford vehicles and some makes between 1977 and 1981. Effective March 1997, Ford discontinued administration of approvals for Type F fluids. However, there are still many vehicles on the road that use Type F. Type F and MERCON fluids are not interchangeable. ATF+3® /ATF+4® DaimlerChrysler has had their own ATF specifications for many years, but as of 1997, Chrysler owners' manuals no longer list DEXRON as an acceptable replacement. ATF+3 is a readily available mineral oil-based ATF that is suitable in any application calling for ATF PLUS® , ATF+2® , or a Type 7176® fluid. Vehicles manufactured after 1999 require ATF+4® , a synthetic-based ATF only available through DaimlerChrysler.

__________________

Forum Guidelines:http://www.automotiveforums.com/vbulletin/guidelines.html "What we've got here is a failure to communicate" |

|

|

|

|

|

#28 | |

|

Resident Chemist

|

Re: 4Runner FAQs

ALTERNATIVE REFRIGERANTS TO R12 AND R134A

Here is an interesting article on alternative refrigerants: A/C: New Alternative Refrigerants by Larry Carley If you have bought any R-12 refrigerant lately, you know it is pretty pricey stuff. Last year, the price peaked at about $20 a pound ($600 for a 30 lb. tank) in some areas of the country. This year some predict the price could shoot as high as $30 to $33 per lb. ($1000 per tank!) if we get a long hot summer. Consequently, people are searching for less expensive alternatives to recharge their A/C systems. NO DROP-INS Though some alternative refrigerants are being marketed as "drop-in" replacements for R-12, there is really no such thing. According to the EPA, the concept of a "drop-in" replacement for R-12 is a marketing myth. Such words imply a substitute refrigerant will perform the same as R-12 under all conditions, that it will require no modifications to the A/C system or changes in lubricant, and that it is compatible with R-12 and can be added to a system that still contains R-12. Federal law prohibits the topping off A/C systems with refrigerants that are different from what is in the system—unless all of the old refrigerant is first removed so the system can be converted to a new refrigerant. The truth is no substitute refrigerant meets all of these requirements. There are, however, a number of alternative refrigerants that have been reviewed by the EPA and have been found to meet the EPA’s SNAP (Significant New Alternatives Policy) criteria for environmental acceptability and usage. The SNAP rules prohibit flammable refrigerants or ones that contain ozone-damaging CFCs. But just because a refrigerant meets the EPA's usage criteria does not mean it is endorsed or "approved" by the EPA, or that it will perform well as a refrigerant. THE ALTERNATIVES There are currently seven alternative refrigerants from which to choose. One is R-134a, which is the only alternative currently approved by all vehicle manufacturers worldwide for new vehicles as well as for converting older R-12 applications. The OEMS say R-134a can perform well in most R-12 systems provided the proper retrofit procedures are followed. The also recommend R-134a because it is a single component refrigerant, unlike most of the alternatives which are blends of two to four ingredients. The OEMS do not like blends because blends can undergo "fractionation." This is when the individual ingredients in a blend separate for various reasons. Fractionation can be caused by chemical differences between the refrigerants (lighter and heavier elements don’t want to stay mixed), different rates of leakage through seals and hoses (smaller molecules leak at a higher rate than larger ones), and different rates of absorption by the compressor oil and desiccant. Fractionation is a concern because it can change the overall composition of the blend once it is in use, which can affect the performance characteristics of the refrigerant. Fractionation also makes it difficult to recycle a blended refrigerant because what comes out of the system may not be the same mix that went into the system. The OEMS also say limiting the alternatives to one (R-134a) simplifies things, reduces the risk of cross-contamination and eliminates the need for multiple recovery machines (EPA rules require a separate dedicated recovery only or recovery/recycling machine for each type of refrigerant serviced). BLENDS Alternative refrigerants that have been found acceptable for automotive applications or are currently being reviewed by the EPA include the following blends:

The suppliers of the alternative blends also insist the fractionation problem is exaggerated and do not foresee any major problems with recovering and recycling their products (recycling blends is currently illegal, but the EPA is reviewing its feasibility). Are blends establishing a niche in the marketplace? One supplier of these products said they sold over a million pounds of their alternative refrigerant last year alone! Most are predicting increased sales as the price of R-12 continues to rise and stockpiles dwindle. MACS FIELD STUDY A field study of various refrigerants conducted by the Mobile Air Conditioning Society (MACS) compared the cooling performance of R-12, R-134a and three blended refrigerants (Freeze 12, FRIGC and McCool Chill-It). The study found that all the alternative refrigerants (including R-134a) did not cool as well as R-12 in the vehicles tested (a 1990 Pontiac Grand Am and a 1987 Honda Accord). But the study did find that the blends outperformed R-134a in the Honda (but not the Pontiac). The increase in A/C outlet temperature with the different refrigerants ranged from less than a degree to almost 11 degrees. ILLEGAL REFRIGERANTS Another class of alternative refrigerants has also appeared on the scene: illegal refrigerants. Some products that have been introduced (OZ-12, HC-12a, R-176 and R-405a) do not meet the EPA’s criteria for environmental acceptability or safety. Flammable refrigerants such as OZ-12 and HC-12a that contain large quantities of hydrocarbons (propane, butane, isobutane, etc.) have been declared illegal for use in mobile A/C applications, but are still turning up in vehicle systems anyway because of their cheap price. Flammable refrigerants pose a significant danger to a vehicle’s occupants should a leak occur. A spark from a cigarette or a switch can ignite the leaking refrigerant causing an explosion and turning the vehicle’s interior into an inferno. It only takes about four ounces of a flammable hydrocarbon refrigerant such as propane or butane to create an explosive mixture inside a typical automobile passenger compartment. Frontal collisions can also release the refrigerant if the condenser is damaged, which could result in a severe underhood fire causing extensive damage to the vehicle. There’s also a risk to service technicians who might encounter leaks while servicing a vehicle or operating recovery/recycling equipment. Merely topping off an A/C system with a flammable hydrocarbon can make the entire charge of refrigerant flammable if the amount added exceeds a certain percentage: 10% in the case of an R-12 system and only 5% with R-134a! That’s only three or four ounces of hydrocarbon depending on the overall capacity of the system. Flammable refrigerants are used in some stationary applications as well as truck trailer refrigeration units because there’s less risk of leakage or fire. Also, the amount of refrigerant is typically much less, only five or six ounces total instead of several pounds. BOOTLEGGERS & COUNTERFEITERS Less dangerous but equally illegal is bootleg R-12 that’s being smuggled into the U.S. from offshore. Though most of the industrialized nations have stopped manufacturing R-12 (production ended here December 31, 1995), R-12 is still being made in some Third World countries including Mexico. Some of this product is finding its way past customs in mislabeled containers or concealed in various ways. The EPA warns that much of the refrigerant it has confiscated thus far is of poor quality, contaminated by air, moisture, R-22 and other substances. The EPA has worked with customs authorities and the FBI to make a number of arrests. Fines for violating the clean air rules can run up to $25,000 per instance. Counterfeiting branded product is another scam that’s being perpetrated to turn a fast buck in today’s market. Cylinders of counterfeit Allied Signal Genetron R-12 have reportedly been turning up in various parts of the country. The cylinders do not contain R-12 but some "unknown" refrigerant. Allied Signal says the counterfeit boxes do not have cut-outs where lot numbers strapped on cylinders would appear and there are no bar codes or white painted stripes on the sides. The number "Q 1167" may also appear on the bottom of the packaging. The cylinders themselves may be marked with a pressure-sensitive decal whereas the genuine product has markings printed on the cylinder itself. CONTAMINATED REFRIGERANT The high price of R-12 has also lead to an increase in incidences of virgin R-12 being adulterated with other less expensive refrigerants. Most technicians assume a tank of virgin refrigerant is pure, but some are finding that’s not the case. Some supplies say they now test every single tank of refrigerant to make sure it contains the proper refrigerant and that the quality of the refrigerant meets specifications. The primary threat of contamination, though, is that of accidentally cross-contaminating refrigerants when vehicles are professionally serviced. Because the law requires all refrigerants to be recovered, there’s a potential risk of contaminating when recovery and recycling equipment is connected to a vehicle. The problem is compounded, many say, by the proliferation of alternative and illegal refrigerants. The dangers of cross-contamination are the effects it can have on cooling performance and component reliability. R-12 and R-134a are not compatible refrigerants because R-134a will not mix with and circulate mineral-based compressor oil (which may lead to compressor failure). Nor is R-134a compatible with the moisture-absorbing desiccant XH-5, which is used in many R-12 systems. Intermixing refrigerants can also raise compressor head pressures dangerously. Adding R-22 (which is used in many stationary A/C systems but is not designed for use in mobile A/C applications) to an R-12 or R-134a system may raise head pressures to the point where it causes the compressor to fail. Straight R-22 can cause extremely high discharge pressure readings (up to 400 or 500 psi!) when underhood temperatures are high. R-22 is also not compatible with XH-5 and XH-7 desiccants used in most mobile A/C systems. R-134a also requires its own special type of oil: either a polyakylene (PAG) oil or a polyol ester (POE) oil. The OEMS mostly specify a variety of different PAG oils because some compressors require a heavier or lighter viscosity oil for proper lubrication (though General Motors does specify only a single grade of PAG oil for most service applications). The aftermarket generally favors POE oil because POE is compatible with both R-12 and R-134a and unlike PAG oil it will mix with mineral oil. Mineral oil, as a rule, should still be used in older R-12 systems. DECISIONS, DECISIONS The use of alternative refrigerants such as blends will likely grow because they’re a cheap alternative to R-12. The OEMs don’t like it, but the EPA has said it will let the market decide the fate of alternative blends. Consequently, you need to be aware of what’s potentially out there and be prepared to handle (or not handle) blends. To minimize the risk of cross-contamination, the EPA requires that each type of refrigerant (including blends) have unique service fittings (permanently installed) and proper labeling. The EPA also requires shops to use a separate dedicated recovery/recycling machine for R-12 and R-134a, plus one or more additional recovery only machines for any other refrigerants that might be used. For this reason, many shops may choose to avoid blends. But fleets may find blends to be an acceptable alternative if they don’t want to convert (or it would cost too much to convert) their vehicles over to R-134a. To protect recycling equipment and customer’s vehicles against cross-contamination or bad refrigerant, service facilities should use a refrigerant identifier to check every vehicle before it is serviced. An identifier can also help the shop monitor the quality of their recycled refrigerant as well as any virgin refrigerant that might be purchased. Most identifiers that are available today can only tell you if the system contains pure R-12, R-134a, hydrocarbons, or R-22 or an "unknown" refrigerant. Each blend has its own characteristic finger print, but because of the fractionation problem getting a precise fix on exactly what’s in a vehicle isn’t as easy as it sounds. The best advise is this: if you don’t know what type of refrigerant is in your vehicle, take it to a shop that has a refrigerant identifier and have it checked. Intermixing different refrigerants can cause cooling problems as well as shorten the life of the compressor. CONTAMINATION ALERT! As the use of alternative refrigerants grows, so does the risk of cross-contamination. A recent survey by the Florida EPA revealed some startling results. When they tested the refrigerant recovery tanks in about 100 shops, here’s what they found: Thirty-eight percent of the recovery tanks showed some type of contamination! Independent repair garages and service shops had the lowest rate of contamination, but it was still 32% (nearly one out of three). Used car dealers were the worst, with 71% of their recovery tanks (almost three out of four) showing signs of contamination. Air contamination was the worst problem, being present in 22% of the tanks tested overall. But cross-contamination between R-12 and R-134a was also found in 15% of the tanks. The most cross-contamination (29%) was discovered in used car dealers. RETROFIT OR NOT? The OEMS say R-12 should be used in all R-12 systems as long as it is available because R-12 provides the best cooling performance in these applications. They say there’s no need to retrofit to R-134a or to use any other refrigerant as long as the system is cooling normally. But if the system requires major repairs such as a new compressor or condenser, the cost to retrofit may be justified. The OEMS say switching an older R-12 system to R-134a does not require a lot of modifications in many instances. Changing the accumulator or receiver-dryer, removing the old compressor oil and replacing the high pressure switch is generally all that’s needed—a job that can usually be done for less than $200. For more information, consider purchasing the R134A RETROFIT GUIDE on this website. OEM as well as aftermarket retrofit kits are now available for such conversions. But some vehicles (namely those with viton compressor seals, compressors that can’t handle higher head pressures or have small condensers) aren’t so easy to convert. Changing some of these vehicles over to R-134a requires extensive and expensive modifications. So for these applications there are no kits or easy answers—other than to switch to a blend refrigerant if R-12 becomes too expensive or is unavailable.

__________________

Forum Guidelines:http://www.automotiveforums.com/vbulletin/guidelines.html "What we've got here is a failure to communicate" |

|

|

|

|

|

#29 | |

|

Resident Chemist

|

Re: 4Runner FAQs

OBDII DTC CODES